This is a cheap way to make a cleanroom, or rather glovebox for working on drives. Works well and will get the small jobs done. When it is something important I usually use a cleanroom but you canuse a glovebox. In addition, when the platters spin, the air bearing created will usually spin off small debris. The drive was actually designed this way. However if you touch it, game over.

This is a cheap way to make a cleanroom, or rather glovebox for working on drives. Works well and will get the small jobs done. When it is something important I usually use a cleanroom but you canuse a glovebox. In addition, when the platters spin, the air bearing created will usually spin off small debris. The drive was actually designed this way. However if you touch it, game over.

It took,

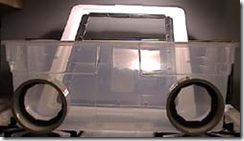

18″ x 24″ piece of plexiglass

rubbermaid 44 qt. clear storage bin

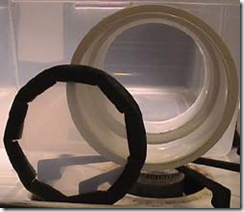

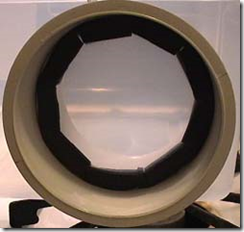

(2) 4″ male pvc adapters

1/8″ thick foam tape

1/8″ drill bit and drill

razor knife

#7 x 1/2″ sheetmetal screws (zip screws)

I had planned on finding some long gloves to use with it attached with large hose clamps but had no luck finding any so far. i will try the bait store next. for now i’ll just use latex gloves with open holes.

to cut the holes in the sides i used the 1/8″ drill bit and drilled holes close together around the lines i traced around the PVC fittings and connected the dots with the razor knife. then the pvc fittings were screwed in(don’t make the holes too big!) i then saved the circles that came out and foam taped around them with notches in either side of the tape around the circle so it could be applied w/o ripples. i will use them as hole plugs to keep the box clean when not in use. i will prolly epoxy some sort of handles or knobs on these so they can be removed easily from the outside of the box.

the hole in the lid was easily cut with the razor knife. the plexiglass was scored with the knife then snaped to size. holes were drilled in the plexiglass then wottled out to be oversized so the plexi didn’t crack when i put the screws in. the lid was a softer plastic and was not drilled. plexiglass was applied with foam tape and zip screws manually with a 1/4″ nut driver. the holes have to be close, i.e. 3″, together to ensure the foam tape sealed (silicone could be substituted here for foam tape)

one of these really isn’t essential for making syringes or even grain to grain transfers, but, after trying agar a few times without one, i decided i needed one.

Be careful with flammable disinfectants and flame in a glovebox, they can (and do) explode! Sanitizer fumes are also highly toxic to mycelia

What is a Cleanroom?

A cleanroom is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment might contain as many as 35,000,000 particles per cubic meter, 0.5 μm and larger in diameter, corresponding to an ISO 9 cleanroom.

If the hard disk needs to be opened up, one has to do it within a cleanroom. The gap between the Read-Write head and the data platter is just a few microns. Any dust particles that get into the gap will induce “crashing” of the Read-Write head onto the data platter (where your magnetic data bits are stored) resulting in total and permanent loss of data.