Fujitsu, M1638TAU drive family

Malfunction signs: The spindle motor does not start

The connection scheme of VCM (Voice Coil Motor) & SPM (Spindle Motor) controller is practically identical for the following drive families: M1614TAU, M1638TAU, MPA30xxAT, MPB30xxAT and MPC30xxAT.

VCM&SPM controller regulates 3-phase motor; it is programmed by the MB9004 processor produced by Fujitsu. There are three modes of spindle motor control: start mode, acceleration mode and stable rotation mode. In the start mode at power-up Power Monitor (MP3771) sends a “reset” signal to the microprocessor (MB9004) and the VCM & SPM controller. Microprocessor uses a serial channel to program internal registers of VCM & SPM controller for a start and charges the pump capacitor of the controller using the “Charge pump” signal. Charge volume determines the current which will flow to the spindle motor. As soon as the start-up capacitor is charged sufficiently the microprocessor programs SPM controller for a start mode, then ~ 1,3А current flows to the spindle motor. Controller generates phase switching signals. The spindle motor at that begins rotation generating self-induced EMF. The controller detects EMF and notifies the microprocessor about that; the latter uses the signal for rotation control. In the acceleration mode the microprocessor speeds up phase switching and measures spindle motor rotational speed until it reaches 5400 RPM. When the speed is reached the controller switches to stable rotation. In that mode microprocessor calculates the time required for one spindle motor revolution on the basis of the phase signal and adjusts the rotational speed charging or discharging the pump capacitor. Adjustment control (charge/discharge) is performed every 1/6 spindle revolution.

The complexity of diagnostics is determined by the fact that SPM controller monitors EMF generated during spindle rotation and at an attempt of spindle spin-up it makes just 2 – 3 phase switches which are difficult to track using oscilloscope. If the spindle does not begin rotation (for whatever reason) the controller, as a rule, either switches off or retries its attempt after some time. Thus, if you use a regular oscilloscope, you can see only presence of pulses falling within a certain range, which is insufficient for complete diagnostics. In an ideal case we would recommend using 3-channel oscilloscope with memory function operating in the automatic recorder mode. Probably such device is not really commonplace. Therefore it is possible just to check the presence of pulses for motor phases.

VCM & SPM controller is a quite reliable microchip and it rarely goes out of order. More frequently a spindle motor does not start because of other malfunctions. Still, if the chip fails such failure is usually caused by overheating with clearly visible traces on chip case. During repair of the start circuit you should check the Stop Spindle signal from the MB3771 chip. The signal forces parking of magnetic heads and stops the spindle motor with keys Q8 and Q9. Active level of that signal in the parking mode is “1”, in the operational drive mode it is “0”. If a spindle motor begins to spin up you can check the operation of output keys of HA13525A chip controlling phase signal with oscilloscope. To do so select 10 ms/div sweep with 2V/div amplification (it is advisable to use the 1:10 multiplier). A phase may be diverted by a disrupted Q8 or Q9 key. HA13525A and HA13525B chips are compatible from top downward, i.e. in models belonging to the M1638TAU and MPA drive families both of those chips can be used. In MPB and MPC drive families only HA13525B is allowed.

Manufacturer: Fujitsu, drive families: MPB, MPC

Malfunction signs: A drive begins to detect a higher own capacity than the actual rated value, the so-called “megalomania”.

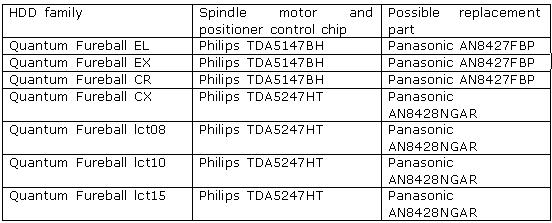

That malfunction is quite frequent in the above-mentioned drive families; it is caused by corruption of firmware in Flash ROM chip on the control board of the drive. Those drive families employ Flash ROM chips using 64К structure based on 16-bit words, programming voltage is 5 or 12 V, package type is PLCC44.

Elimination of that malfunction requires just reprogramming of Flash chip by recording a known good firmware of the corresponding version. Version number in Fujitsu drives is indicated in the lower right corner of the label over HDA below bar code and it looks like: xyy-zzzz, where x –means the month when the drive was manufactured in hexadecimal notation, yy – means version prefix and zzzz – means the actual firmware version, e.g.: С02-2009. For version compatibility in MPB and MPC drive families just the actual version match is sufficient, the prefix and month of manufacture are not important.

Manufacturer: Fujitsu, MPG3xxxAT/AH drive family

Malfunction signs: Quite unexpectedly for user and user data a drive is no longer identified in PC BIOS.

We should note that this very drive model has broken all records of failures, which happen in most cases after a year of operation, just after completion of the warranty period. The main cause of the malfunction was in the Cirrus Logic CL-SH8671-450E chip. It can hardly be replaced with a working chip because those microcircuits were produced for a special Fujitsu order and the manufacture of that drive family was discontinued long ago. However, there is a method of “revival” and “revitalizing” a malfunctioning chip which allows extending HDD life a little. However, if you ignore drive “hangings” and do not take due steps (at least backup valuable data) the table of S.M.A.R.T. logs in firmware zone will be gradually overfilled and the drive will additionally corrupt its modules in firmware zone, which cannot be restored without specialized software.

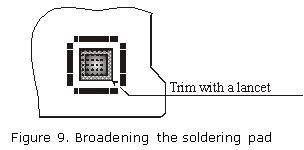

One of the versions explaining the cause of problems with those chips is the use of a new polymer compound during production of chip case. The compound decomposes under the influence of increased temperature in humid conditions producing phosphoric acid. But it is just a version; we may never learn whether it is so or not. However, one thing is known for sure: if you unsolder that chip, remove old solder from its pins and contact pads on the board, flush the location for the chip and then solder it back the drive will begin to work properly.