Background of the Magnetic disc drive head alignment system Invention

Magnetic disc drives for recording digital data are well known to the art. In such drives it is desirable to achieve the highest recording density possible, such recording density being a function of both the number of annular tracks per radial inch of disc surface and the number of bits per inch along each track. The optimum number of tracks on the individual discs is dependent on the precision of the head positioning system and on the precision in the alignment of the various read/write heads in the disc drive. The system of the present invention provides for the precise alignment of each of the read/write heads in the disc drive so that an optimum number of tracks per radial inch of the individual discs may be achieved.

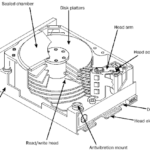

The discs incorporated into present-day disc drives are usually referred to as a disc pack, and these discs are stacked one above the other to be sensed by a plurality of magnetic read/write heads mounted in vertical alignment and positioned by a single actuator. In one type of present-day head positioning system used in disc drives, one of the heads (servo disc surface) and one disc surface are dedicated to the generation of debit position signals for an associated servo system. A plurality of servo tracks are recorded in concentric circles on the dedicated servo disc surface, and the servo head produces the debit signals which are indicative of the relative position of the servo head and the servo tracks.

For interchangeability of the disc packs, the various tracks recorded on each of the disc surfaces must be closely aligned with the pre-recorded servo tracks on the dedicated servo disc surface so that the read back of the data from each disc pack is possible on recorders other than the one on which the data was recorded.

When the servo head is held in registry with the servo tracks on the dedicated servo disc surface, and the remaining read/write heads are aligned with the servo head, the remaining heads will be properly positioned over the corresponding data tracks on other disc surfaces. As mentioned above, an objective of the present invention is to provide a system which enables the remaining magnetic heads to be precisely aligned with the servo head, so that they will all be properly positioned with respect to the data tracks on the other disc surfaces.

The normal procedure for assuring that the read/write heads are in vertical alignment is to place a disc pack into the disc drive which has pre-recorded and precisely positioned servo tracks on all the disc surfaces. Such pre-recorded servo disc packs are commercially available for use in head alignment and are usually referred to as “CE” (Customer Engineer) packs. By reading the signals from the individual heads, as the heads read the various servo tracks, and by feeding such signals to a display device, each head can be adjusted until it is in precise tracking engagement with the tracks on the surface of the corresponding disc.

The present invention, as mentioned above, provides a system for reading debit signals generated by the various heads of a disc drive, as these heads read the various servo tracks on the pre-recorded servo disc pack, and it provides digital outputs representative of any misalignments of the various heads. Each head can then be adjusted to a position at which the digital output signal for that head indicates precise alignment.